Copper composite panel is composed of upper-surface copper, back-surface copper and the non-combustible core layer respectively connected with the high molecular adhesive film. The structure is copper – core – copper, which saves a lot of copper material than using solid copper panel. By contacting with air, the copper surface will gradually change into old copper, then green patina with the decorative effect more gorgeous and elegant. The surface is smooth and easy to be processed, which is mainly used for the decoration of the exterior wall of the building.

The history of using copper in architecture dates back to 10000 years ago. As one of the nobal metal, copper has a better performance than other metal in physical. Some of the world's most distinguished modern architects have relied on copper. Examples include Frank Lloyd Wright, who specified copper materials in all of his building projects; Michael Graves, an AIA Gold Medalist who designed over 350 buildings worldwide; Renzo Piano, who designed pre-patinated clad copper for the NEMO-Metropolis Museum of Science in Amsterdam, etc.

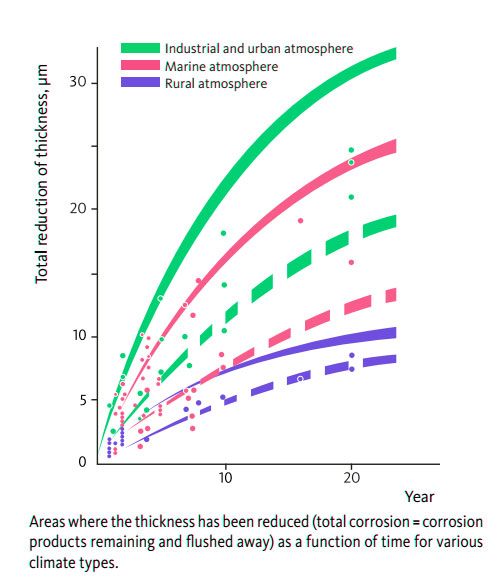

| Copper corrosion diagram | Different environmental corrsion | ||||

|  | ||||

| Copper | Stainless Steel | Aluminum | |||

| Lifespan(years) | 200 | 100 | 100 | ||

| Embodied Energy(MJ/m2) | 103.3 | 157.2 | 115.4 | ||

| CO2 equivalent emissions(kg/m2) | 6.6 | 10.9 | 7.5 | ||

| Specific density(g/cm3) | 8.9 | 7.93 | 2.7 | ||

| Copper color image |

|

| PSYSICAL PROPERTIES OF Cu DHP | |

| Density | 8.9 g/cm3 |

| Melting point | 1083℃ |

| Specific thermal capacity at 20℃ | 0.385kj(kg℃) |

| Coefficient of linear expansion at 20-100℃ | 16.8 × 106/℃ |

| Coefficient of linear expansion at 20-300℃ | 17.7 × 106/℃ |

| Modulus of elasticity | 118 000 N/mm2 |

| Shear modulus | 44 000 N/mm2 |

| Electrical conductivity at 20℃ | ca 52 MS/m / ca 90 % IACS |

| Thermal conductivity at 20℃ | ca 365 W/(m ℃) |

| Resistivity at 20℃ | ca 20 nΩ m |

| Temperature coefficient for resistance at 20℃ | 0.00275 ℃ |

| Temperature coefficient for resistance at 0-100℃ | 0.00354 |

| Product available | |

| Thickness | 3mm 4mm 5mm 6mm |

| Width | 1200mm(maximum) |

| Length | 2440mm, 3200mm(Or according to Customer needs) |

| Copper thickness | 0.3mm to 0.6mm |